Research and Development

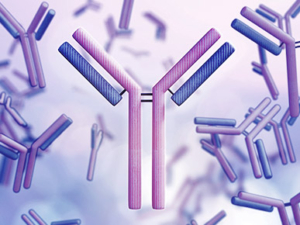

At Gene Bio Medical, we utilize innovative technologies such as mouse hybridoma technology to produce high-quality monoclonal antibodies. Custom antibodies can be developed against customer-specified antigens, with every step of the process carefully discussed and documented to ensure customer satisfaction.

Process Outline

1. Immunization:

Mice are immunized with customer-specified antigens. To improve the overall success rate, we assist in antigen preparation and antibody purification, as higher purity generally increases the likelihood of generating useful antibodies.

After receiving your request and reviewing the antigen, our senior scientists design the immunization protocol. This plan is then shared with you for approval (some antigens may require coupling). Antibody specificity in mouse serum is monitored regularly using ELISA, Western Blotting, or other validated test systems. Serum samples are provided for your review before moving to the next stage: cell fusion.

2. Cell Fusion & Clone Screening:

Upon approval, mouse spleen cells are fused with myeloma cells. Hybridoma clones are screened using ELISA, and positive clones are expanded. You may determine how many clones should be saved or cultured, depending on the number of monoclonal antibodies required. If needed, hybridoma supernatants can be provided for further testing.

3. Cloning & Antibody Production

Once antibody activity and monoclonality are confirmed, hybridoma cells can be injected into mice to produce ascites. The ascites fluid is collected, frozen, and—if required—samples are provided for verification.

4. Antibody Purification

Following ascites collection, our researchers select the optimal purification method to balance high purity with strong biological activity. A detailed purification strategy is shared for your approval before technicians proceed with the purification stage.